CNC Machining Service

By using CNC machining, prototypes and production parts can be machined in as little as 1 day.*

Request an online quote today.

Certifications

ISO 9001: 2015

IATF 16949:2016

40,000+

Machined parts each month

50+

CNC machines

100+

Plastic and metal materials

CNC Machining Services

CNC Milling

3, 4 and 5-axis machining of plastic and metal parts. Machine up to 66" in size*

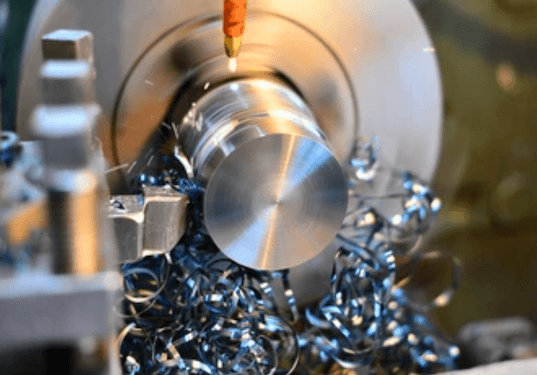

CNC Turning

Tight tolerances and finishing capabilities, as fast as 2 days.

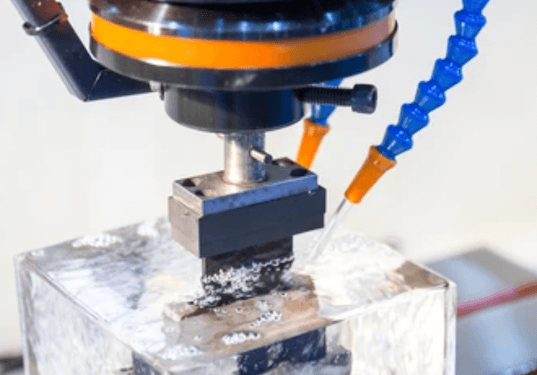

Sinker EDM

Create blind holes and complex cavities using sinker EDM machining.

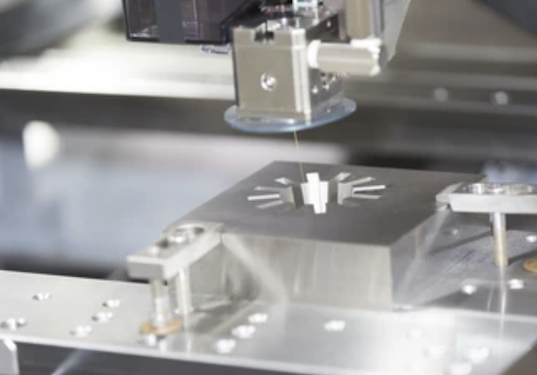

Wire EDM

Cut a 2-dimensional profile out of very thick material using wire EDM

CNC Service Applications

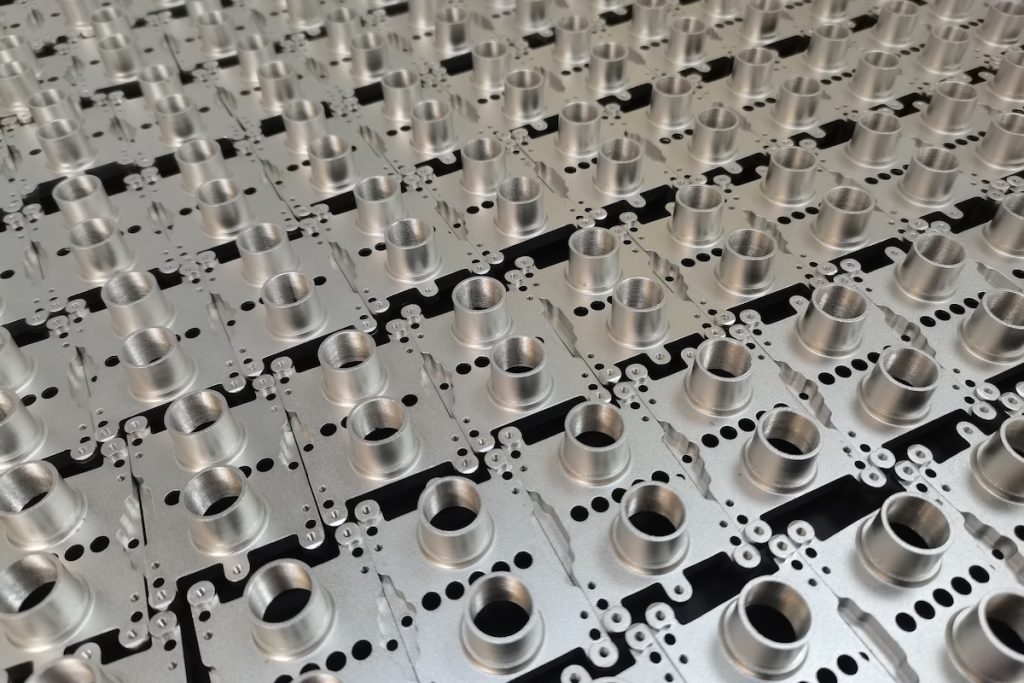

Low Volume Production

RP Group offers full production-quality parts in volumes ranging from a single piece to a few thousand pieces.

Appearance Prototypes

We take pride in producing the finest appearance models and prototypes with very high detail in any material you want.

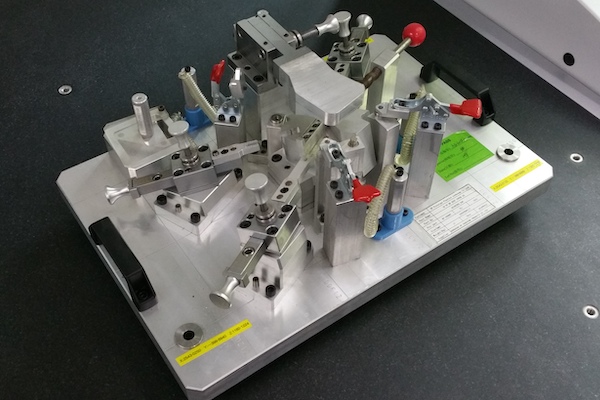

Fixtures and Gauges

We engineer fixtures and gauges to your specifications and may offer recommendations based on our in depth understanding of Geometric Dimension and Tolerancing (GD&T).

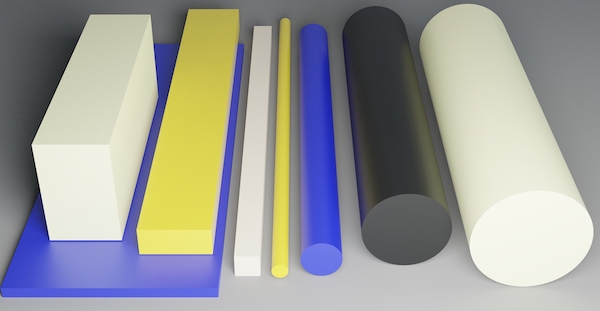

CNC Machining Materials

Metals

- Aluminum

- Brass

- Copper

- Stainless Steel

- Steel Alloy

- Magnesium

- Titanium

Plastics

- ABS

- Acetal

- CPVC

- HDPE

- LDPE

- Nylon

- PEEK

- PEI

- PET

- PMMA

- Polycarbonate

- Polypropylene

- PPSU

- PS

- PSU

- PTFE

- PVC

Why choose RP Group for CNC Machining?

Design for Manufacture

Our experienced engineers will analyse your design and provide feedback on manufacturability and look for opportunities to reduce cost.

Communication

We are always quick to respond to questions via email, phone, web meeting or chat to ensure your project turn around is as fast as possible.

Quality Reports

All projects where 2D drawings are provided come with a dimension report before parts are shipped. CMM reports can be produced on demand at no additional charge.

Transparent Progress Reports

We provide progress and tracking information through our customer portal. Videos and photos of the parts can be confirmed before parts are shipped out.

Time to Market

We have a infinite capacity via our vetted supply chain outside our own in house capabilities so we have the flexibility to manage all projects large and small.

Full Service Manufacturing

We can offer a wide range of materials, processes, finishes and sub-components to make us your one-stop supplier for your whole project.

Top 5 Manufacturing Technologies That Increase Efficiency and Speed

Surface finish

Besides our in house finishing capabilities of painting, printing, polishing and sand/bead blasting we have a many sub suppliers that provide additional finishes such as powder coating, anodizing, chrome plating, PVD etc. Please let us know what your finishing requirements are and we are more than likely be able to help.

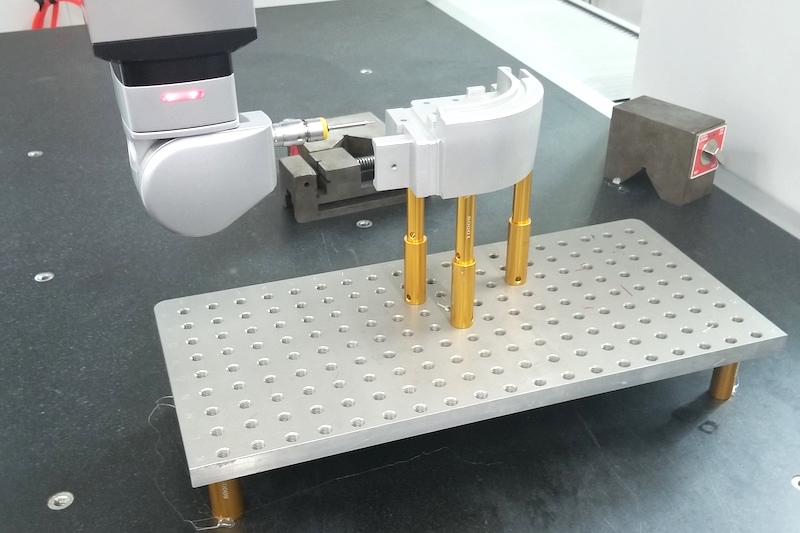

Metrology

At all four of our RP Group manufacturing locations, we have a fully equipped metrology department to ensure your part's quality compliance. Experienced engineers in fixture and gauge design from GD&T.

- Programmable

- 3D Scanning

- Fixture and gauge manufacture

CNC Machining FAQs

Rapid prototyping and the capacity to quickly generate full-scale production parts are two of CNC machining's main benefits. It enables for tight tolerance machining of CNC components of all sizes and gives a high level of precision and accuracy in manufacturing parts. It also provides the most flexibility in terms of volume, cost, lead times, and the materials and finishes available.

CNC turning and CNC milling are the two most common CNC machining operations. Drilling, gear hobbing, and electrical discharge machining are some of the various machining operations.

Aerospace, automotive parts production, medical machine manufacture, transportation, defense, and marine industries, as well as oil and gas industries and electronics, all use CNC machining. CNC machining has helped these industries become more efficient at mass-producing specialized CNC parts.

The standard CNC machining tolerance is ± 0.005" or 0.13mm. Tolerances are the allowable range for a dimension. This means that if a CNC machining tool has a tolerance of ± 0.01 mm, the tool can have a deviation of 0.01 mm in every cut. Nexuvo’s CNC machining service can produce CNC parts with tolerance as low as ± 0.0052 mm with a drawing. Where there is no drawing, all CNC parts are produced to our ISO 2768 medium standard. We can also machine to tighter tolerances of ±0.025mm or ±0.001 with an attached engineering drawing highlighting the critical features.